Transformer Oil Regeneration Systems

The growth in renewable energy production and the increase in the rating requirements for modern transformers creates a more demanding operating environment for the insulating materials. Especially, transformer insulating oil has to deal with greater electrical stresses than ever before. Therefore, the transformer oils in today’s transformers need to be at their optimum working conditions to ensure the safety of the equipment. Utility companies constantly have to maintain their transformer oil, so that it has the right dielectric strength, low residual water content, low acidity, low IFT and no sulphur.

Advanced transformer oil deterioration requires full-on transformer oil regeneration to ensure transformer safety

The transformer oil deteriorate over time as it draws in moisture and changes its chemical structure. As air slowly leaks into the transformer during its lifetime, the insulating fluid gets in contact with water and oxygen. The high temperatures during transformer operation as well as the other materials within the transformer facilitate the oxidization of the transformer oil and the cracking of the oil’s hydrocarbons.

This leads to acidic components and sludge within the transformer which exponentially accelerate the oil deterioration. The acidic components attack the materials within the transformer – while the sludge severely decreases the cooling properties of the insulating fluid. Consequently, the electrical and chemical properties of the insulating fluid become worse and worse as time progresses.

That is why, performing proper and timely maintenance on the transformer oil is essential to keep the transformer’s insulating system in the optimal operating range. Only then can the transformer oil successfully perform its functions of serving as a dielectric material and effective coolant.

The HERING EOK-TORS transformer oil regeneration systems give you the best of transformer oil regeneration and purification in one high-performance system

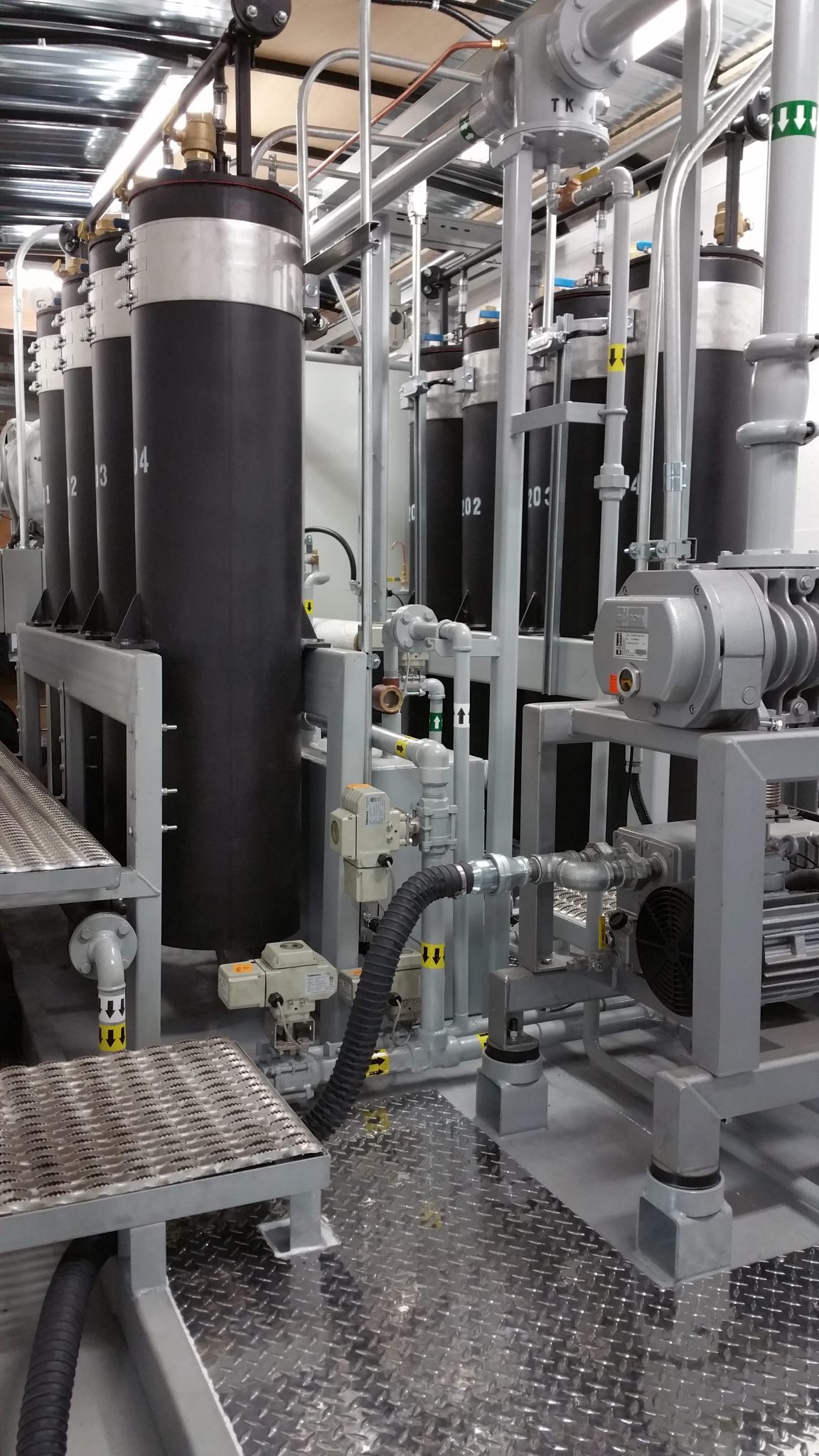

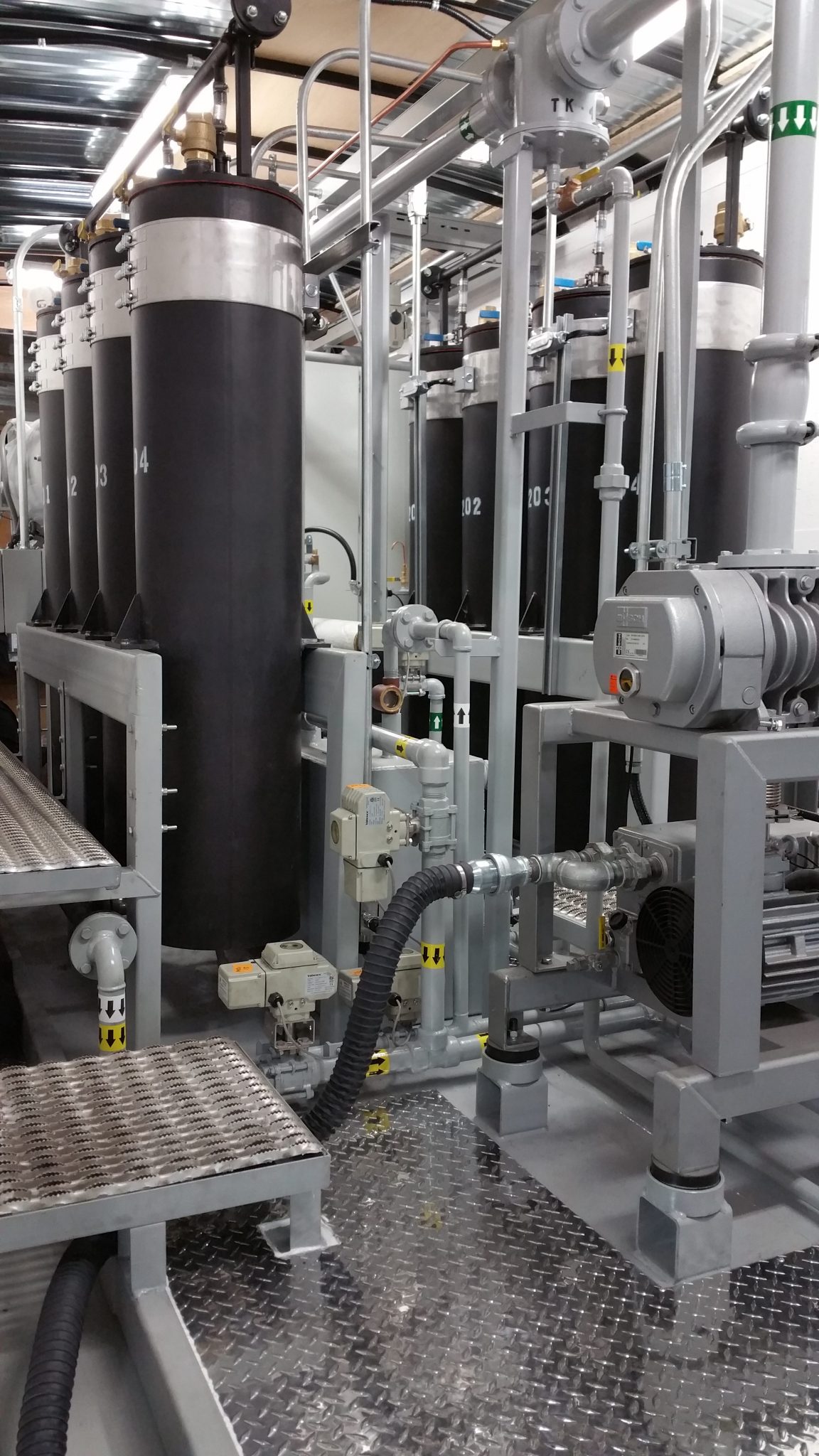

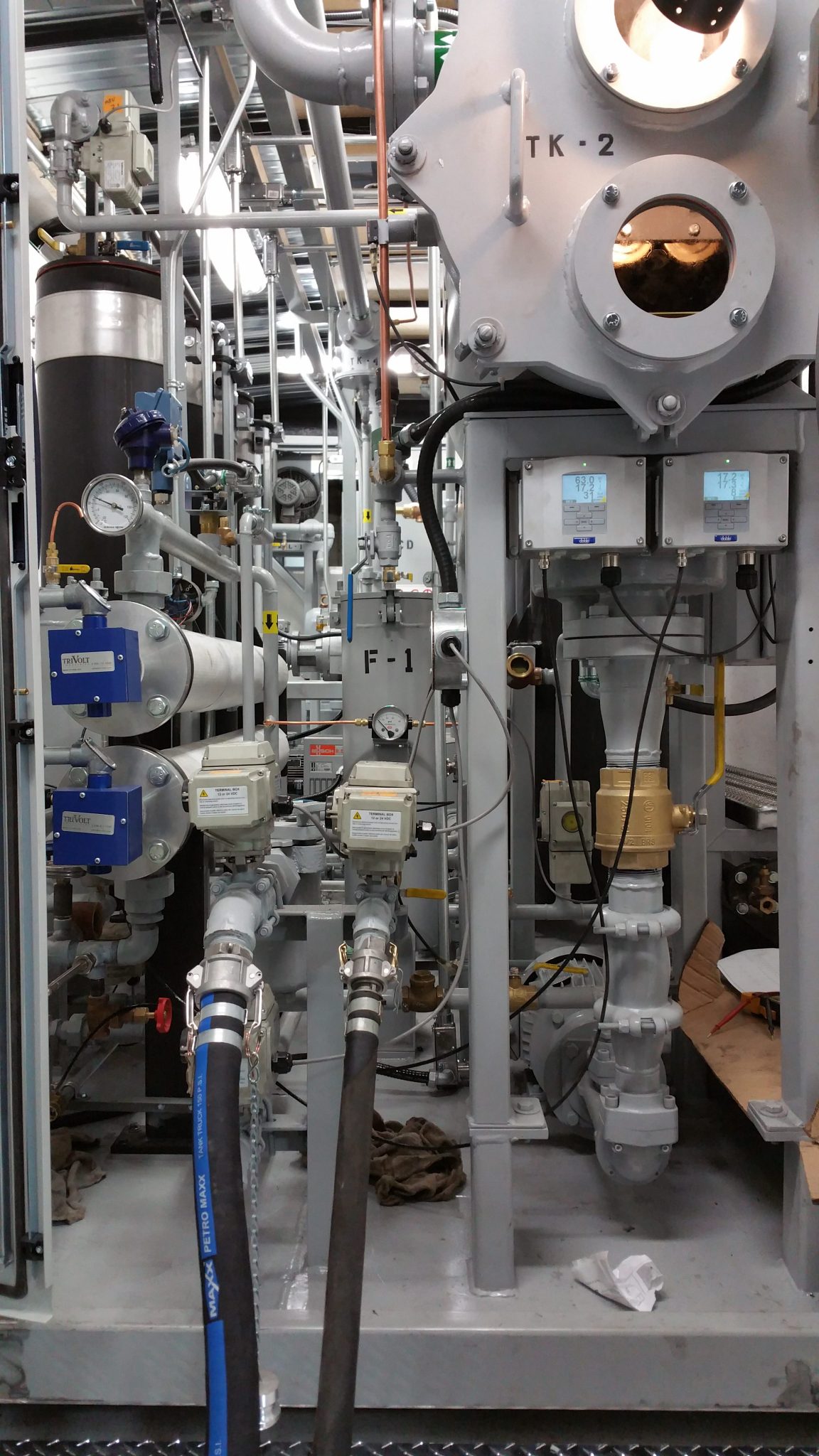

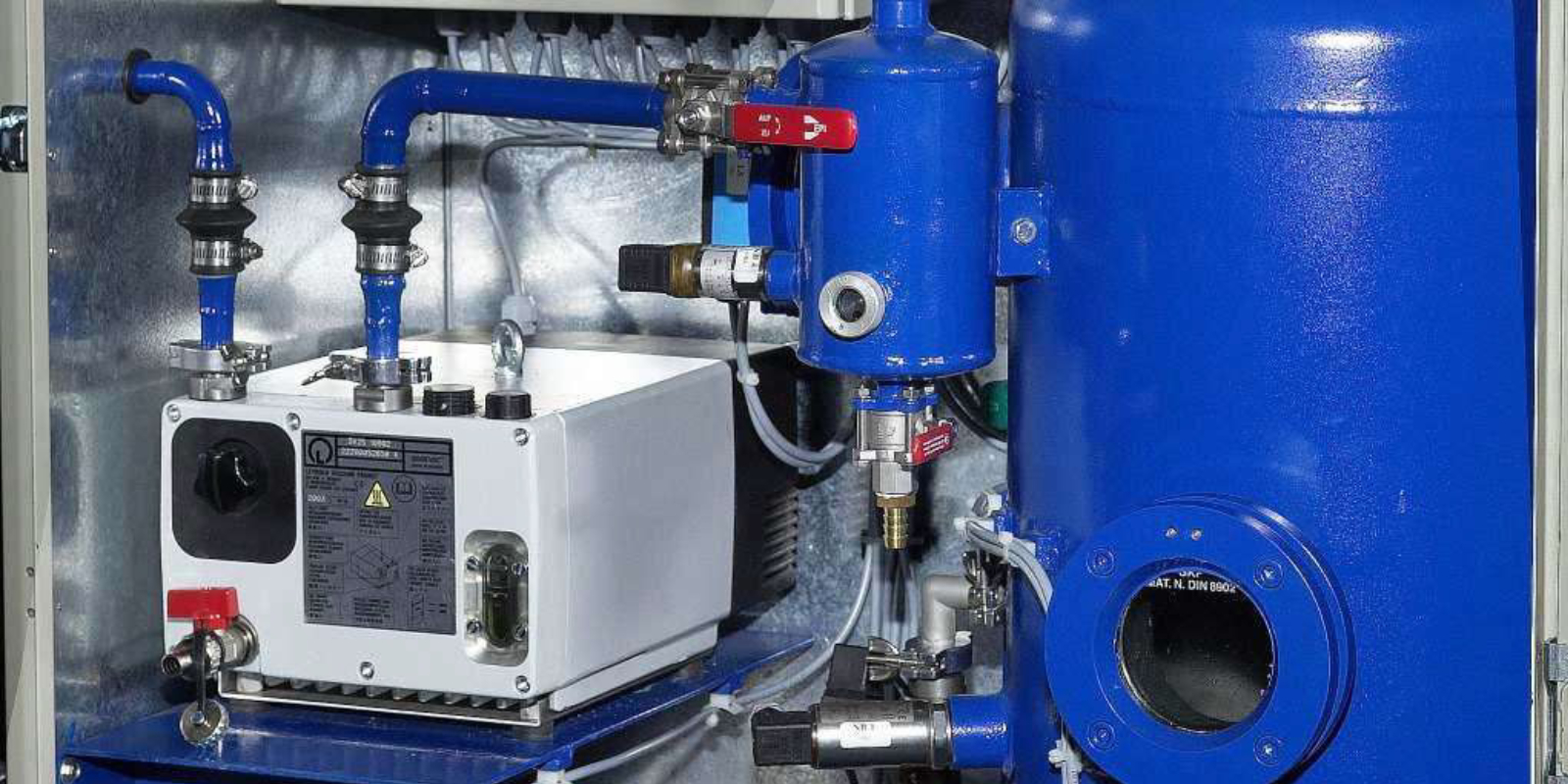

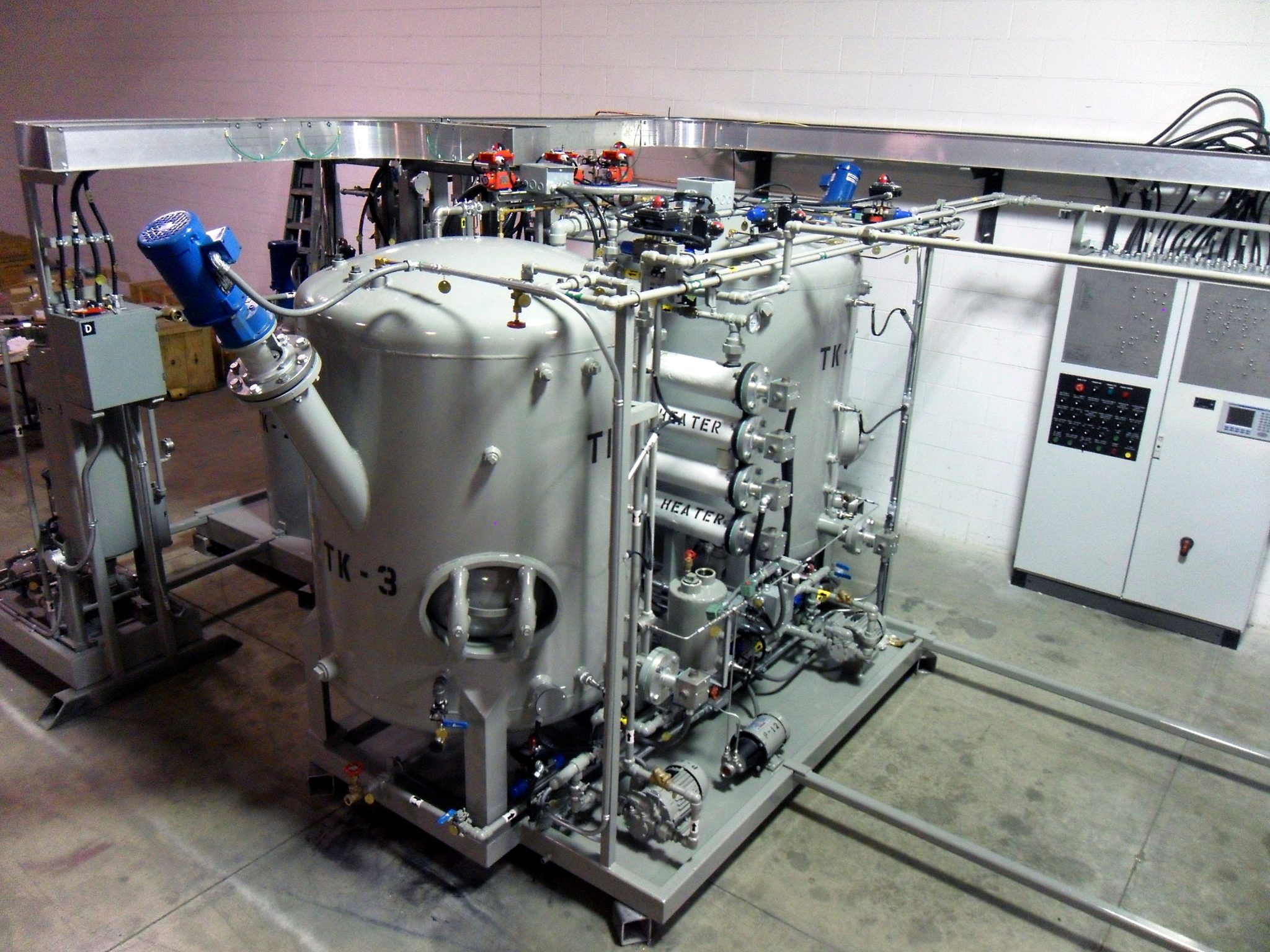

The proper treatment of transformer insulating oil involves the regeneration, dehydration and degasification of the oil. The HERING EOK-TORS transformer oil regeneration systems perform all three tasks in the highest efficient and most effective manner. Using our transformer oil regeneration equipment provides you with the all the benefits of our best-in-class EOK oil purification technology and the added power of the TORS regeneration columns. All our systems are made in Germany and powered by German Engineering to provide you with the highest quality possible.

Regeneration is 20% to 50% cheaper than new oil

Life extension with efficiency boost

Removal of corrosive sulfur (DBDS) and deterioration products

No downtime due to online & offline regenerating capabilites

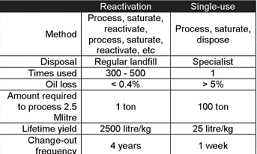

There are typically two ways to regenerate deteriorated transformer oil to as-new or even better-than-new state: single-use Fullers Earth regeneration and multiple-use reactivation regeneration. Our HERING EOK-TORS transformer oil regeneration plants are reactivation systems that combine higher efficiency, longer lifetime and increased flexibility when compared to single-use Fullers Earth units. The HERING EOK-TORS transformer oil regeneration systems first strain, heat and filter the oil before sending it through a series of regeneration columns. In these columns, our special highly adsorbent HERING PHÖNIX regeneration medium restores the oil’s properties in an initial step. Then, our HERING EOK oil purification system performs a full dehydration and degasification of the transformer oil. The quality of this process is higher than that used by most transformer oil producers. Therefore, your transformer oil will – in most cases – be restored to better-than-new conditions and at least to as-new conditions. Throughout the operation of the HERING EOK-TORS transformer regeneration system, our sophisticated reactivation process reactivates the absorbent medium in parallel to normal operation. Hence, you can use the HERING EOK-TORS to continuously regenerate transformer oil without the plant shutting down.

Do you only want a high quality oil purification plant instead? Then, our HERING EOK Series Transformer oil purification systems are the best solution for you.

Are you rather interested in full scale transformer drying ovens for a more comprehensive treatment of your transformer? Then, our HERING transformer drying oven product line might be the right choice for you.

Still not found what you were looking for? Take a look at our products page for our most popular products or get in touch for customized solutions. We will build the right product for you!

Transformer Oil Regeneration Systems

Regeneration systems typically remove the by-products of aging from used transformer oil. Transformer oil mainly consists of a mixture of hydrocarbons which deteriorate over time. Deterioration is mainly due to contamination, overheating, electrical stress, and oxidation. This causes byproducts to form in the oil which increase acidity (neutralization number) and decrease the interfacial tension of the oil. The sludge that forms during this process and the other by-products lead to a loss in dielectric properties. At this point, the transformer oil must be replaced or fully regenerated to ensure the efficient and safe operation of the transformer. There are traditionally two approaches to the removal of these contaminants, either approach will result in the used oil being restored to ‘as new’ state: Reactivation or single-use fullers earth application.

Our EOK-TORS® Series powered by Redragon reactivation type oil regeneration systems combine higher efficiency, longer lifetime and increased flexibility when compared to single-use fullers earth:

General Specification

This specification describes the technical layout, the performance and the workmanship of a transformer oil regeneration system, Type EOK-TORS.

IntroductionThe growing consumption of electrical energy continuously demands higher degrees of durability and safety of operation of the generating, transforming, switching and conduction electrical devices. Transformer oil is in an environment that leads to a degradation in its desired properties. Over time, even in a proactive maintenance program, transformer oil loses its insulating properties and its cooling properties. The rating requirements and drive to tighter tolerances of modern transformers and electrical apparatus results in greater electrical stress in insulating material and fluids. To handle these stresses, oils are required to have better dielectric strength, and lower residual water content must be maintained to reduce the speed of oil aging. The timeous and proper treatment of these insulating fluids will result in the improvement of the properties of the entire insulating system of power transformers and will extend the effective lifetime of the asset.

The principal functions of the insulating fluid are to serve as a dielectric material and an effective coolant. To perform these functions, the insulating fluid must possess specific qualities at the time of initial impregnation of the transformer core and filling of the tank at the manufacturer’s factory and which must be maintained at the same level in field operation if optimum performance is to be guaranteed. Typically, these qualities are well-defined by international and national standards authorities e.g. IEC 296, BS 148, SABS 555, etc.

Transformer oils deteriorate with time and the decay begins the moment the transformer is brought into service. High temperatures, the presence of oxygen and water, the catalytic action of the materials within the transformer, all combine to result in oxidation and cracking of the transformer oil. The by-products of this oxidative process are acidic and the long-term effect of exposure to these products results in an ever-increasing rate of deterioration of the transformer and its oil. The resulting sludge build-up reduces the cooling effects of the oil driving the whole decay mechanism at an increasingly accelerated rate. Although there is no specific acidity level at which action should be taken to treat the oil (generally this action level is determined by the asset value), historical data shows that the acid number becomes exponential around the 0.2 mg KOH/g oil level.

Our EOK-TORS and TORS are used not only to stop the deterioration/ aging process of the oil, but to completely reverse the process. After the regeneration the oil is comparable with new oil, in many cases the oil quality is even better.

Technical Data Sheet

| Expected Performance Data | |||

|---|---|---|---|

| Parameter Measured | Water content | < 5 | ppm |

| after 3 passes | Gas content | < 0.3 | vol% |

| Breakdown voltage | >75 | kV/2.5mm | |

| Acidity | <0.01 | mg KOH/g oil | |

| Tan Delta | <0.001 | at 90°C | |

| IFT | >45 | dynes/cm | |

| Oxidization - acidity | <0.2 | mg KOH/g oil | |

Regenerating your transformer oil with the EOK-TORS® Series provides you with,

- Economic advantages – regenerated oil is 20 to 50% cheaper than buying new.

- Life extension with efficiency boost – transformer oil can be regenerated more than six times without efficiency loss.

- Control of transformer oil as strategic asset – use of EOK-TORS® makes you independent from oil suppliers.

- Removal of corrosive sulfur – Dibenzyl Disulfide, one of the main causes for transformer failures, gets removed expanding your equipment’s lifespan.

- No downtime due to regenerating – EOK-TORS® units can be operated on energized transformers as effectively as on un-energized transformers.

Hering Systems are remarkable for their efficient and robust design, as well as their ease of operation and maintenance. We install only high quality components from Germany, respected West European brand manufacturers. Our systems are designed for long lifetime, reliability and effective operation. Each plant is custom-made and delivered with all required aggregates to leave nothing to be desired. Together, we will develop the perfect solution for you and your company. We are looking forward to serving you!